Page 6 - Screw Conveyor.ppp

P. 6

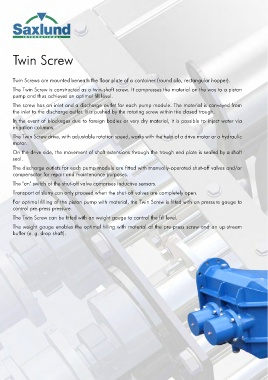

Twin Screw

Twin Screws are mounted beneath the floor plate of a container (round silo, rectangular hopper).

The Twin Screw is constructed as a twin-shaft screw. It compresses the material on the way to a piston

pump and thus achieves an optimal fill level.

The screw has an inlet and a discharge outlet for each pump module. The material is conveyed from

the inlet to the discharge outlet. It is pushed by the rotating screw within the closed trough.

In the event of blockages due to foreign bodies or very dry material, it is possible to inject water via

irrigation columns.

The Twin Screw drive, with adjustable rotation speed, works with the help of a drive motor or a hydraulic

motor.

On the drive side, the movement of shaft extensions through the trough end plate is sealed by a shaft

seal.

The discharge outlets for each pump module are fitted with manually-operated shut-off valves and/or

compensator for repair and maintenance purposes.

The "on" switch of the shut-off valve comprises inductive sensors.

Transport of slurry can only proceed when the shut-off valves are completely open.

For optimal filling of the piston pump with material, the Twin Screw is fitted with an pressure gauge to

control pre-press pressure.

The Twin Screw can be fitted with an weight gauge to control the fill level.

The weight gauge enables the optimal filling with material of the pre-press screw and an up-stream

buffer (e. g. drop shaft).