Page 2 - Hydraulic Rotor.ppp

P. 2

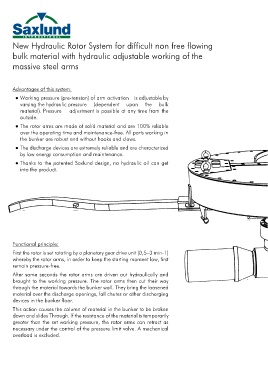

New Hydraulic Rotor System for difficult non free flowing

bulk material with hydraulic adjustable working of the

massive steel arms

Advantages of this system:

● Working pressure (pre-tension) of arm activation is adjustable by

varying the hydraulic pressure (dependent upon the bulk

material). Pressure adjustment is possible at any time from the

outside.

● The rotor arms are made of solid material and are 100% reliable

over the operating time and maintenance-free. All parts working in

the bunker are robust and without hooks and claws.

● The discharge devices are extremely reliable and are characterized

by low energy consumption and maintenance.

● Thanks to the patented Saxlund design, no hydraulic oil can get

into the product.

Functional principle:

First the rotor is set rotating by a planetary gear drive unit (0,5–3 min-1)

whereby the rotor arms, in order to keep the starting moment low, first

remain pressure-free.

After some seconds the rotor arms are driven out hydraulically and

brought to the working pressure. The rotor arms then cut their way

through the material towards the bunker wall. They bring the loosened

material over the discharge openings, fall chutes or other discharging

devices in the bunker floor.

This action causes the column of material in the bunker to be broken

down and slides Through. If the resistance of the material is temporarily

greater than the set working pressure, the rotor arms can retract as

necessary under the control of the pressure limit valve. A mechanical

overload is excluded.